Gradient Materials

July 28, 2014

It's unknown who coined the expression, "Change is good," and that's a good thing, since he would be a hated man. No one likes change, and you can be certain that when you hear some

corporate manager say, "Change is good," bad things are about to happen. If there must be change, people would like the change to be gradual. A

decade time scale, preferably a

lifetime, would be nice.

Some things in

nature happen abruptly, and some things happen gradually. The

universe, itself, started abruptly, with the

Big Bang, and the

quantum nature of

matter is inherently abrupt. The

phase transitions of

macroscopic systems can be either gradual (

first order), or abrupt (

second order). An example of a

first order phase transition would be

melting, and an example of a

second order phase transition would be

superconductivity. In superconductivity, you're either

superconducting, or you're not.

Many useful

materials are

layers of one material on another.

Printed circuit boards, in which a

copper layer forms

conductive paths on a

glass-

epoxy or

ceramic substrate, are one example. An extreme example is

integrated circuitry in which layer after layer of

semiconductors and

metals are used to form some useful

electronics. Since different materials have different

mechanical and

thermal properties, bad things can happen at the abrupt

interface between one layer and another.

You can often eliminate the problems of an abrupt interface by using multiple material layers to approximate a gradual change. A good example of this is the

anti-reflection coating on a

glass camera lens. The

refractive index of glass is about 1.5, so there's quite a bit of

reflection of a

light wave in

air (refractive index, 1.0) as it strikes the lens.

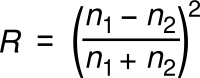

Plugging these values into the

reflectance equation,

where

n1 and

n2 are the two refractive indices (in any order), gives you a

reflectance R of about 4% at

normal incidence. Adding an intermediate layer with a refractive index of 1.225 gives 1% at each interface, so the reflectance is halved.

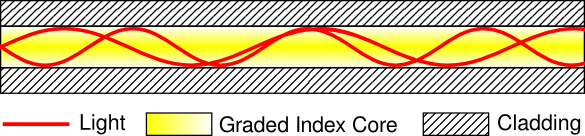

An example of a graded material. A multimode optical fiber with a graded-index core has lower loss than a step-index fiber. (Illustration by Stanisław Skowron, via Wikimedia Commons.)

One major problem with layered materials is the difference in

thermal expansion between layers. This becomes a major problem when the layer is deposited at high

temperature, but used at

room temperature. At one time, I was developing thick

iron garnet layers on

transparent garnet substrates for

magneto-optical sensors. The layers were prepared at about 800

°C by

liquid phase epitaxy, and when they were cooled to room temperature you would often find that the

wafers were bowed; or, worse yet, they would

crack from the mismatch

strain.

Often it's advantageous to have a surface that's highly strained. In a process called

shot peening, or ball peening, an

alloy's surface is pelted by hard metal balls to induce a

compressive surface strain. The strain profile is gradual through the alloy, since there are more impact

forces at the surface than below the surface.

The purpose of such a layer is to enhance

fracture toughness, since the compression tends to close any cracks at the surface before they can grow larger. Many years ago I was a member of a

research team that used compressive layers on articles made from

single crystals to increase their fracture toughness.[1-3]

An international team of

scientists from the

Chinese Academy of Sciences (

Beijing, China),

North Carolina State University (Raleigh, NC), and the

Nanjing University of Science and Technology (Nanjing, China) have recently

published their research on the properties of material gradient structures. Their approach was to

mimic the

microscale-nanoscale change in the

grain-size of some

biological materials to obtain better mechanical properties for

technological materials.[4-6]

As I've often mentioned, a material derives its properties from both its

chemical composition and its

microstructure. Most materials are

polycrystalline; that is, they are composed of a myriad of small single crystals packed together, and the size and orientation of these grains determine many of the material properties, including its

strength and fracture toughness. Smaller grains offer

hardness, and larger grains offer

ductility.

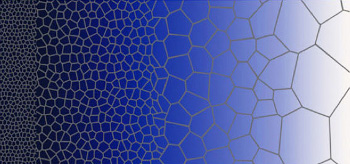

Some natural materials derive their excellent mechanical properties from a

hierarchical structure, mixing smaller and larger structures to give both strength and ductility. I wrote about the hierarchical structure of

spider silk in a

previous article (Spider Silk, March 12, 2012). What the Chinese-North Carolina research team did was to create materials with a gradient in grain size from large grains in the interior to small grains at the surface to derive benefit from their different properties.[6]

Representation of a gradient structured polycrystalline material

(NCSU image by Yuntian Zhu.)

The research team tried this gradient approach on many metals, including copper, iron,

nickel and

stainless steel, and the mechanical properties were improved for them all.[6]

Experiments were also done for

interstitial-free steel. Although this material can be made with 450

MPa tensile strength, it has low ductility, having a strain limit of about 5%. The gradient process produced material with 500 MPa tensile strength, and a 20%

rupture strain.[6]

These improved mechanical properties arise from conversion of an applied

uniaxial stress to

bi-axial stress generated by the gradient. This results in the the accumulation and interaction of

dislocations that leads to additional

work hardening that supplements that of non-gradient materials. The gradient technique is a novel path to superior mechanical properties for an otherwise optimized material.[4-5]

Says

Xiaolei Wu,

professor of

materials science at the

Institute of Mechanics of the Chinese Academy of Sciences and lead

author of the two papers on this research,

"We think this is an exciting new area for materials research because it has a host of applications and it can be easily and inexpensively incorporated into industrial processes."[6]

The research team will now investigate whether this gradient structure approach can be used to engineer

corrosion resistance in existing materials, and also improve their

fatigue and

wear properties. This research was funded by the

U.S. Army Research Office.[6]

References:

- J. Marion, D.M. Gualtieri, and R.C. Morris, "Compressive Epitactic Layers on Single Crystal Components for Improved Mechanical Durability and Strength," J. Appl. Phys., vol. 62, no. 5 (September 1, 1987), pp. 2065-2069.

- Robert C. Morris, Devlin M. Gualtieri, Dave Narasimhan, and Philip J. Whalen, "Epitaxially Strengthened Single Crystal Aluminum Garnet Reinforcement Fibers," U.S. Pat. No. 5,572,725, November 5, 1996

- Devlin M. Gualtieri, Robert C. Morris, Dave Narasimhan, and Philip J. Whalen, "Single Crystal Oxide Turbine Blades," U.S. Pat. No. 5,573,862, November 12, 1996.

- X.L. Wu, P. Jiang, L. Chen, J.F. Zhang, F.P. Yuan, and Y.T. Zhu, "Synergetic Strengthening by Gradient Structure," Materials Research Letters, July 2, 2014, DOI: 10.1080/21663831.2014.935821. This is an open access article with a PDF file available here.

- XiaoLei Wua, Ping Jianga, Liu Chena, Fuping Yuana, and Yuntian T. Zhub, "Extraordinary strain hardening by gradient structure," Proceedings of the National Academy of Sciences, May 5, 2014, DOI: 10.1073/pnas.1324069111. This is an open access article with a PDF file available here.

- Matt Shipman, "Inspired by Nature, Researchers Create Tougher Metal Materials," North Carolina State University Press Release, July 2, 2014.

Permanent Link to this article

Linked Keywords: Corporation; manager; decade; life expectancy; nature; universe; Big Bang; quantum mechanics; matter; phase transition; macroscopic; system; first order phase transition; melting; second order phase transition; superconductivity; superconducting; material; layer; printed circuit board; copper; electrical conductor; conductive; glass fiber; epoxy; ceramic; substrate; integrated circuit; semiconductor; metal; electronics; mechanics; mechanical; thermal; property; interface; anti-reflective coating; glass; camera; lens; refractive index; reflection; electromagnetic radiation; light wave; atmosphere of Earth; air<; reflectance equation; reflectivity; reflectance; normal incidence; Stanisław Skowron; Wikimedia Commons; thermal expansion; temperature; room temperature; iron; garnet; transparency; transparent; magneto-optical; sensor; celsius; °C; liquid phase epitaxy; wafer; fracture; crack; strain; shot peening; alloy; compression; compressive; force; fracture toughness; research; single crystal; scientist; Chinese Academy of Sciences; Beijing, China; North Carolina State University (Raleigh, NC); Nanjing University of Science and Technology (Nanjing, China); scientific literature; publish; biomimicry; mimic; microscale-nanoscale; crystallite; grain; biology; biological; technology; technological; chemical composition; microstructure; polycrystal; polycrystalline; ultimate tensile strength; hardness; ductility; herarchy; hierarchical structure; spider silk; nickel; stainless steel; experiment; interstitial; steel; pascal; MPa; tensile strength; ductile fracture; rupture strain; uniaxial stress; bi-axial stress; dislocation; work hardening; Xiaolei Wu; professor; materials science; Institute of Mechanics of the Chinese Academy of Sciences; author; corrosion resistance; fatigue; wear; U.S. Army Research Office; Robert C. Morris, Devlin M. Gualtieri, Dave Narasimhan, and Philip J. Whalen, "Epitaxially Strengthened Single Crystal Aluminum Garnet Reinforcement Fibers," U.S. Pat. No. 5,572,725, November 5, 1996; Devlin M. Gualtieri, Robert C. Morris, Dave Narasimhan, and Philip J. Whalen, "Single Crystal Oxide Turbine Blades," U.S. Pat. No. 5,573,862, November 12, 1996.